Orange Plastics

Low volume injection molding –

For prototypes, designs and small production runs

Efficient injection molding in low volumes

Low volume injection

molding

At Orange Plastics, we also specialize in low volume injection molding, ideal for prototypes, test products, or limited production runs. With quantities ranging from a few dozen to several thousand parts, we offer fast and flexible production without high tooling investments, while maintaining the same precision and surface quality as large-scale production.

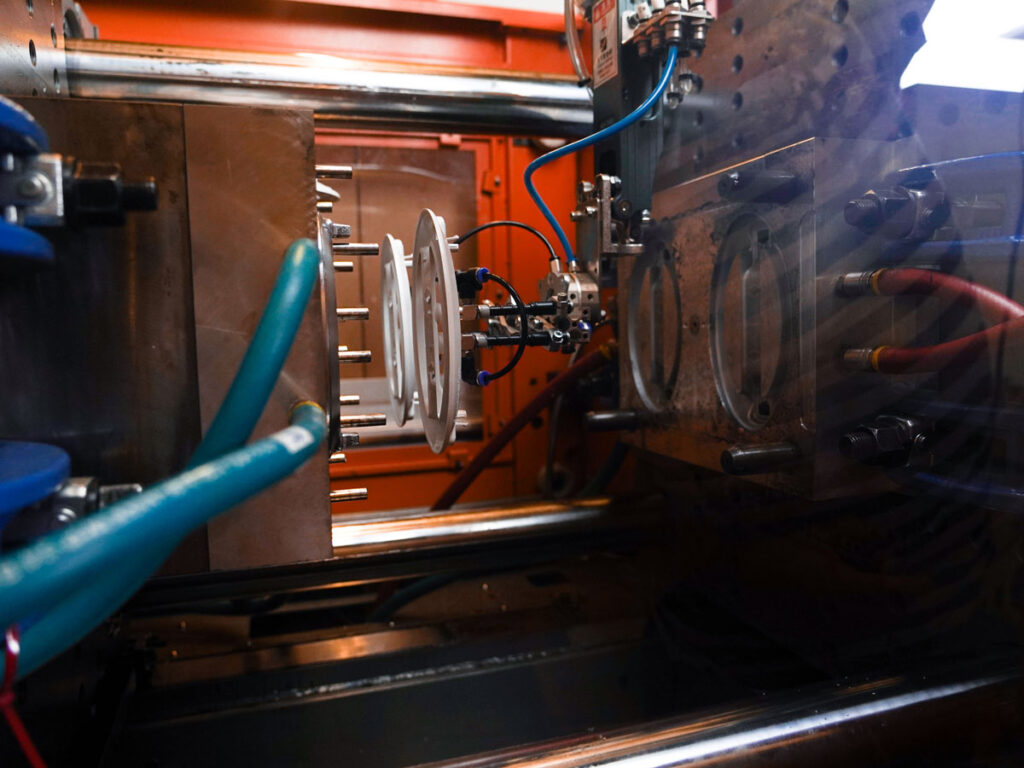

The process

How does low volume injection molding work?

Low volume injection molding works technically the same as traditional injection molding. The difference lies in the approach: we use less complex molds and can easily convert a test mold into a production mold with minor modifications. This allows us to produce quickly, efficiently, and without high startup costs.

1. Material preparation

Plastic granulate (e.g. ABS, PP, or PC) is dried and fed into the injection molding machine. Even for low volume production, we use production-grade materials, ensuring results that are representative of larger series.

2. Injection & molding

The molten plastic is injected into the mold under high pressure. Depending on the batch size, we often use single-cavity or simplified molds, which helps keep tooling costs low.

3. Cooling & solidification

The plastic solidifies in the mold and takes its final shape. Thanks to short cycle times, we can quickly iterate between prototypes or low volume production runs.

4. Ejection & finishing

After cooling, the product is automatically ejected from the mold. If required, light post-processing is carried out, such as removing gates or performing small assembly operations.

5. Inspection & process optimization

Each component is inspected for dimensional accuracy, strength, and surface finish. Since low volume runs are often part of product development, process parameters can be adjusted flexibly to implement improvements quickly.

The advantages explained

The advantages of low volume injection molding

Low volume injection molding offers flexibility and speed without compromising quality. It allows rapid testing, refinement, and market introduction while keeping production costs under control. Ideal for prototypes, special orders, or innovative products.

- Lower initial costs: Simplified or single-cavity molds keep tooling investments low, ideal for prototypes or pilot runs.

- Fast lead times: Low volume batches can be scheduled flexibly and produced within a few weeks.

- Design freedom and adaptability: Small design changes can easily be implemented between production runs without significant additional costs.

- Reduced risk: Perfect for market introductions or engineering tests without immediate investment in large-scale production.

- End-use quality production: Parts are produced using the same materials and tolerances as mass production, ensuring fully representative prototypes.

Recycled materials

Which materials do we use for low volume production?

At Orange Plastics, we produce low volume series using a wide range of plastics, from rigid to flexible or elastic materials, standard thermoplastics, high-performance engineering plastics, and sustainable alternatives. Each material has unique properties that affect functionality, processability, and product quality. Our specialists are happy to advise you on which plastic best suits your low volume series and production process.

Other plastics

Is your desired material not listed? There’s a good chance we have experience with it. We work with many more types of plastics than those mentioned above, but we don’t list them all on our website. Feel free to contact us to discuss the possibilities.

Methodology

Our other services

Your product within 6 to 10 weeks

Pricing and

lead times

Low volume injection molding offers flexibility and speed, allowing you to test multiple iterations before committing to full-scale production. Exact costs and lead times depend heavily on the product design and mold configuration.

- Batch sizes: Low volume production is ideal for prototypes or limited production runs.

- Iterations: Design adjustments or refinements can be implemented easily between production runs.

- Costs and complexity: These vary depending on product design and mold requirements.

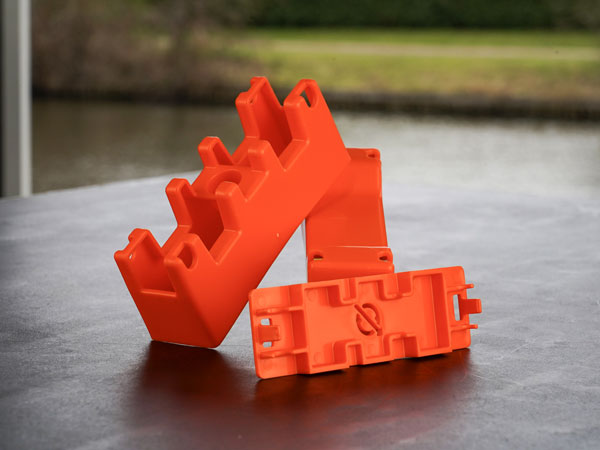

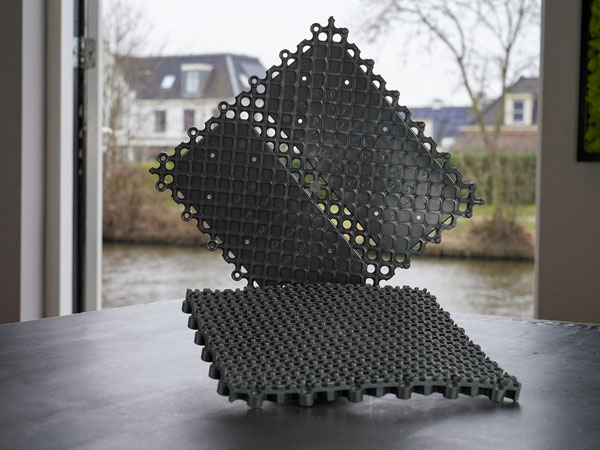

Our cases

Examples of injection molding projects

FAQ

Frequently asked questions about low volume injection molding

Low volume production is possible from just a few dozen parts. This is feasible thanks to flexible tooling and an efficient process setup, keeping startup costs manageable.

Up to several thousand parts is considered low volume. Beyond that, we typically convert the test mold into a production mold and transition to traditional injection molding processes to optimize cost and lead time.

Yes. Low volume injection molding is technically identical to large-scale production. You receive the same precision, surface finish, and reliability, only in smaller quantities and with faster time to market.

Orange plastics

Turn your product idea

into reality?

Testimonials

Clients of Orange Plastics

Our experience with Orange Plastics is very positive. Their expertise in 3D modeling, injection mold development and production, and injection molding itself is impressive. The flexible and thoughtful approach - from development to assembly - has helped us enormously in the success of our project. All in all a great club to work with!

Sylvan Boonstra

The collaboration with Orange Plastics went smoothly from the beginning to the end of our project because the lines are very short and they can switch quickly. In addition, they deliver good quality products within the tight deadline. All in all, a company that we can definitely turn to for future projects!

Julia van Bloois

Very fast and quality service. We will definitely come back for our next project.

Jen Rossey

Good service and generous thoughts. Even after the product has been delivered, they continue to help.

Dennis Bartels

Excellent cooperation with Orange Plastics during the development and production of our product. Together we developed a beautiful, high-quality product. In short, a nice company to do business with.

Cornelis van der Kuijl