Orange Plastics

Overmolding – Multiple colors, one

product

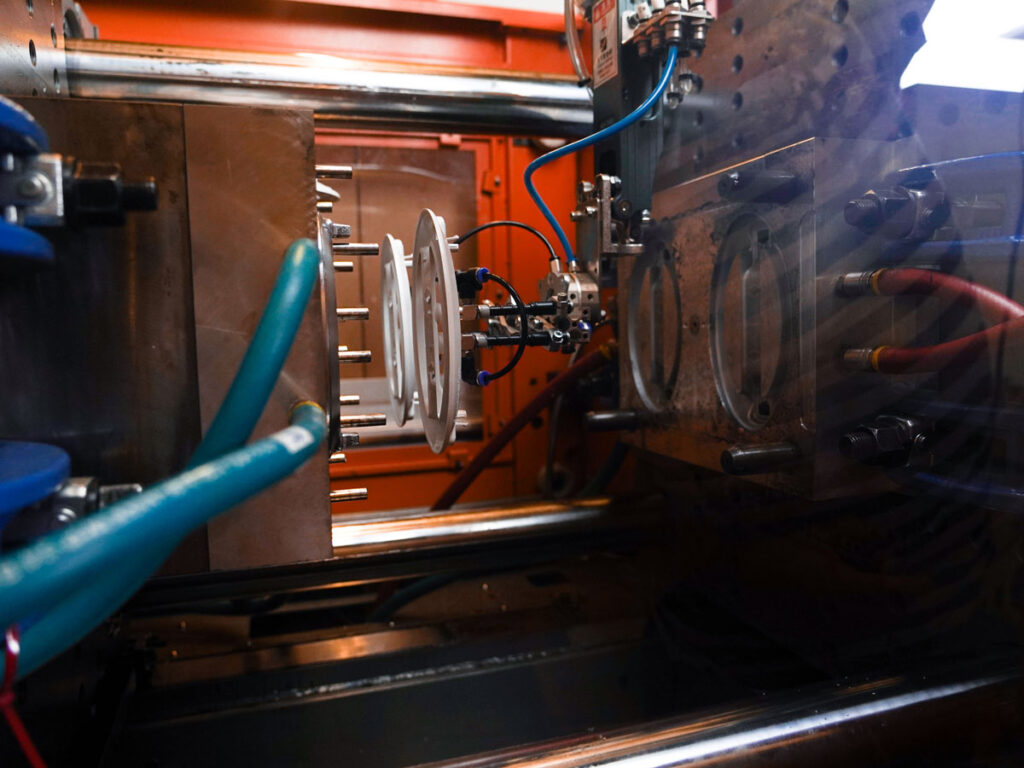

Injection molding

Injection molding of two or more components

In two-component overmolding, two polymer melts are processed sequentially in the same mold. This results in one seamless component with multiple functions: from grip surfaces and seals to color accents or transparent windows. The process delivers stronger products, reduced assembly requirements, and higher overall quality. It is ideal for consumer goods, technical components, and design-driven products.

The process

How does overmolding work?

1. Material preparation

Two types of plastic granulate (e.g. PP and TPE, or two colors of ABS) are prepared separately. Each material is dried and fed into its own injection unit. Both screws plasticize the material into a homogeneous melt.

2. First injection & forming

The first plastic (the base component) is injected into the mold. This forms the load-bearing or structural part of the product. After solidification, this component remains in the mold or is transferred to a second mold position.

3. Second injection & forming

A second plastic is injected against or over the first component. This may serve as a soft-touch layer, seal, or second color. Both materials bond thermally or mechanically into one strong, integrated assembly.

4. Cooling & solidification

Both materials cool in a controlled manner via integrated cooling channels. This ensures precise dimensions, optimal adhesion between layers, and a high-quality surface finish.

5. Inspection & process optimization

Products are inspected for color distribution, adhesion, dimensional stability, and surface structure. Process parameters can be adjusted per component to ensure consistent quality and minimal waste.

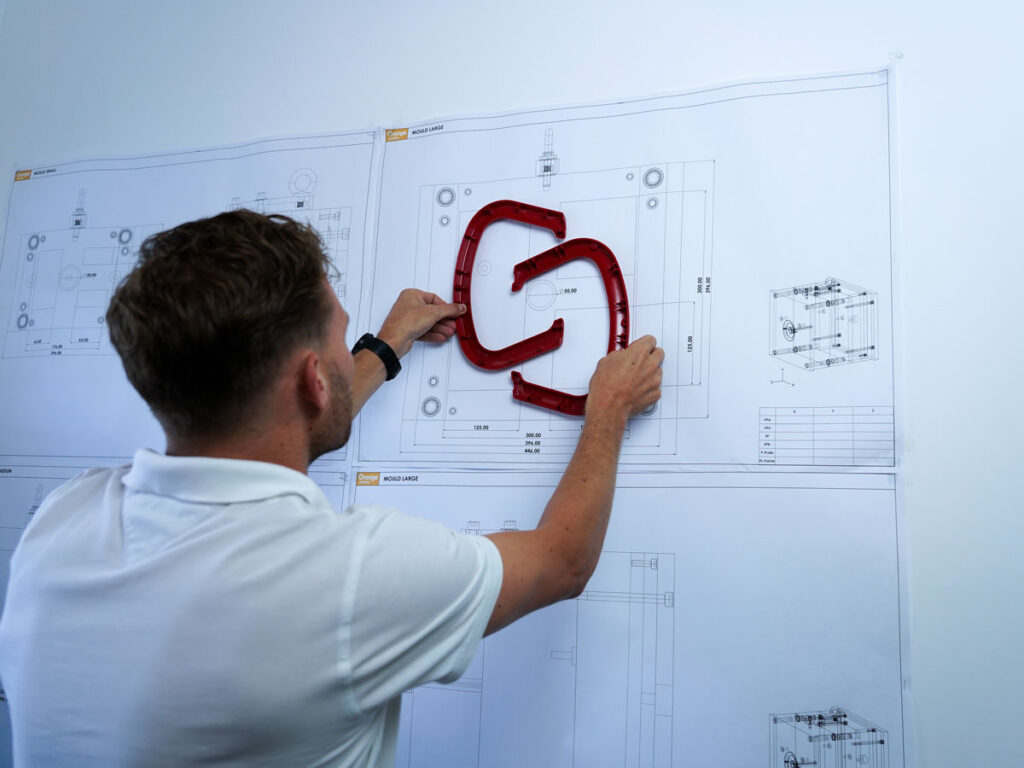

Color & function combined

The advantages of overmolding

Overmolding offers innovative possibilities for product design. It allows different materials and colors to merge seamlessly, simplifies production processes, and enables both functional and aesthetic solutions.

- Strong material bonding: The two plastics bond directly in the mold, resulting in a durable, seamless connection.

- Two colors or materials in one process: Functional and aesthetic integration without post-processing or assembly.

- Efficient and cost-effective: Fewer assembly steps and lower failure rates lead to an economical production process.

- High design freedom: Complex geometries, soft-touch zones, and color contrasts are easy to achieve.

Rigid and flexible components

Which materials are suitable for overmolding?

At Orange Plastics, we work with a wide range of plastics for overmolding—from rigid to flexible or elastic plastics, standard thermoplastics, high-performance engineering plastics, and sustainable alternatives. Each material has its own unique properties and applications. Our specialists are happy to advise you on which plastic best suits your product and production process.

Other plastics

Is your desired material not listed? There’s a good chance we have experience with it. We work with many more types of plastics than those mentioned above, but we don’t list them all on our website. Feel free to contact us to discuss the possibilities.

Methodology

Our other services

Your product within 8 to 14 weeks

Pricing and

lead times

- Two or more components being combined into one part

- A slightly slower cycle time per component

- Fewer parts produced per day due to increased complexity

- More complex molds and specialized systems

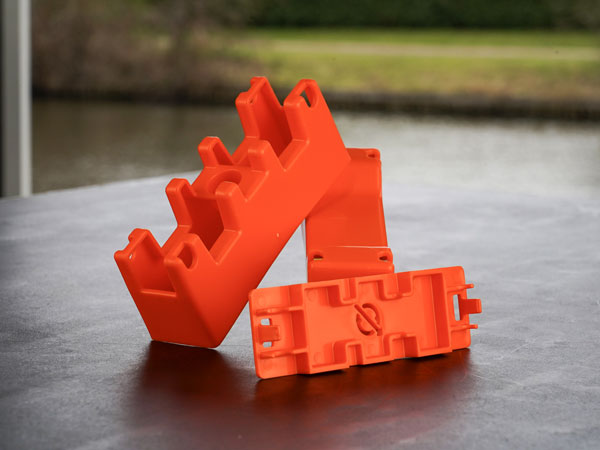

Our cases

Examples of injection molding projects

FAQ

Frequently asked questions about overmolding

Overmolding is an injection molding process in which two different plastics are combined into a single component. This results in strong, multifunctional parts without the need for additional assembly.

- Combines materials for added strength or functionality

- Enables multiple colors or finishes in one product

- Reduces assembly time and costs

- Ideal for complex components with integrated functions

Overmolding is typically feasible from several thousand units. This depends on mold design and complexity, but smaller series are often possible thanks to our flexible production methods.

At Orange Plastics, we offer both single-shot injection molding and overmolding. Single-shot molding uses one plastic material per product and is ideal for straightforward applications. Overmolding combines two plastics directly into one product without additional assembly, resulting in strong, functional, and aesthetically refined components.

Orange plastics

Turn your product idea

into reality?

Testimonials

Clients of Orange Plastics

Our experience with Orange Plastics is very positive. Their expertise in 3D modeling, injection mold development and production, and injection molding itself is impressive. The flexible and thoughtful approach - from development to assembly - has helped us enormously in the success of our project. All in all a great club to work with!

Sylvan Boonstra

The collaboration with Orange Plastics went smoothly from the beginning to the end of our project because the lines are very short and they can switch quickly. In addition, they deliver good quality products within the tight deadline. All in all, a company that we can definitely turn to for future projects!

Julia van Bloois

Very fast and quality service. We will definitely come back for our next project.

Jen Rossey

Good service and generous thoughts. Even after the product has been delivered, they continue to help.

Dennis Bartels

Excellent cooperation with Orange Plastics during the development and production of our product. Together we developed a beautiful, high-quality product. In short, a nice company to do business with.

Cornelis van der Kuijl