Orange Plastics

Insert molding – Two materials,

one product

Strong plastic–metal combination

Insert molding

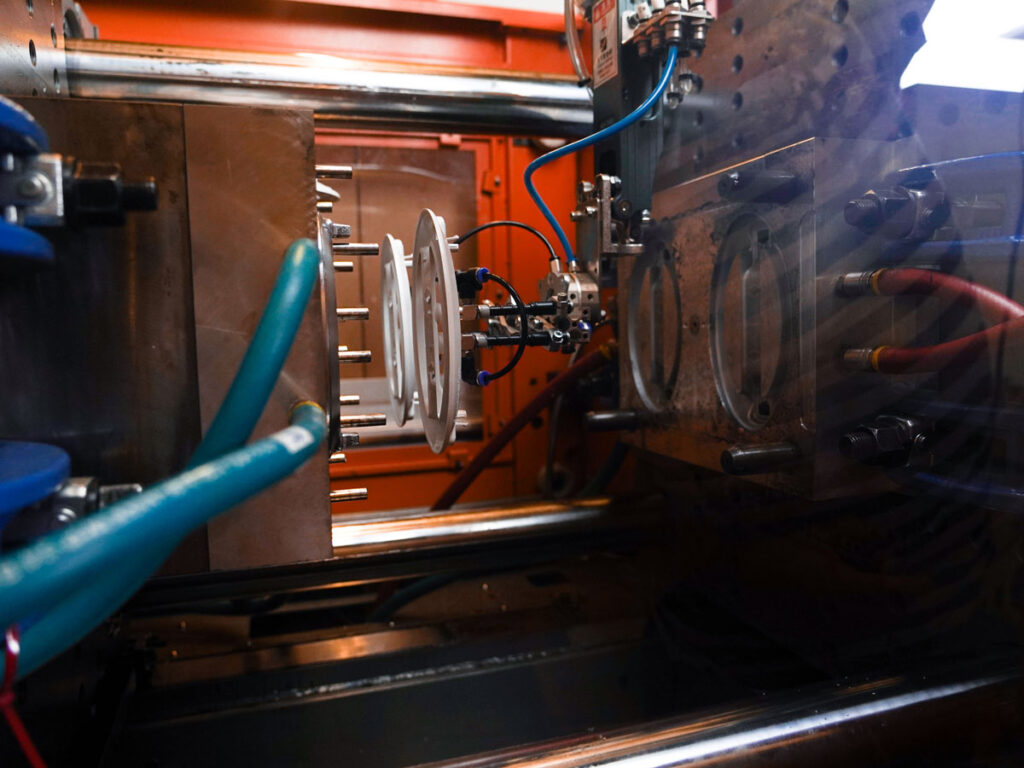

The process

How does insert molding work?

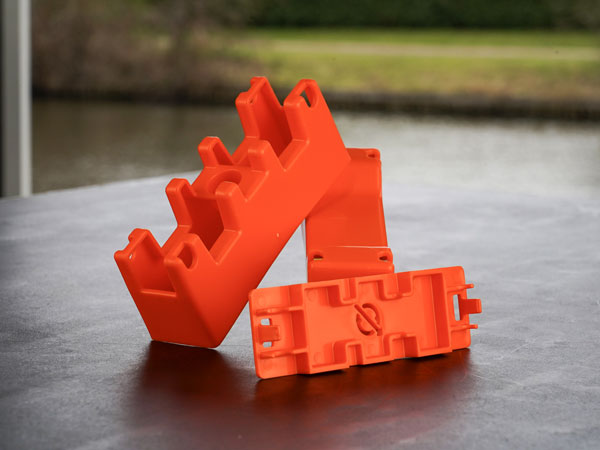

Insert molding is an advanced injection molding technique in which pre-manufactured components (such as metal inserts, threaded bushings, or electronic components) are overmolded with plastic. The result is a single integrated product that combines the strength or functionality of metal with the design freedom and lightweight properties of plastic.

1. Insert preparation

The inserts (e.g. brass bushings, steel pins, or plastic components) are cleaned and positioned in the mold, either manually or using a robot. Accurate positioning is essential to ensure proper bonding and dimensional accuracy of the final product.

2. Material preparation

The plastic granulate (e.g. PA, PBT, or PC) is dried and plasticized in the injection unit into a homogeneous melt. The choice of plastic is matched to the insert material and the required bonding characteristics.

3. Injection & encapsulation

The molten plastic is injected into the mold under high pressure and flows around the inserts. The material bonds mechanically and often thermally to the insert, creating a strong and permanent connection.

4. Second injection & forming

A second plastic is injected against or over the first component. This may serve as a soft-touch layer, seal, or second color. Both materials bond thermally or mechanically into one strong, integrated assembly.

5. Cooling & solidification

During the cooling phase, the plastic solidifies into its final shape. A well-designed cooling system prevents deformation of both the inserts and the plastic and ensures stable dimensional accuracy.

6. Ejection & quality control

After solidification, the assembled component is carefully ejected to avoid damaging the inserts. The parts are then inspected for bonding strength, dimensional accuracy, and surface quality.

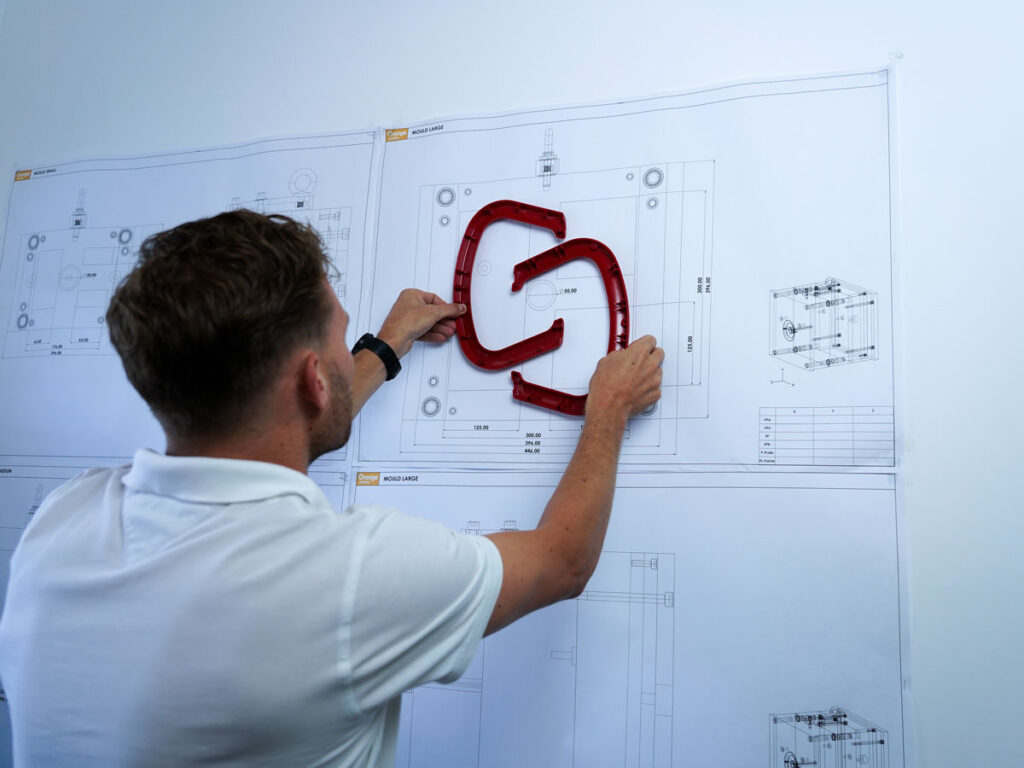

How we do it

The advantages of insert molding

With insert molding, we combine the strength of metal with the design freedom of plastic in one efficient process.

- Strong, durable bonding: The plastic flows directly around the insert and bonds both thermally and mechanically, resulting in a solid, permanent connection.

- Metal and plastic in one product: Threads, contact points, or reinforcements are directly overmolded with plastic—without adhesives, screws, or secondary operations.

- Efficient and cost-effective: Fewer assembly steps and lower failure rates lead to an economical production process.

- Design freedom and precision: Complex geometries and integrated functions are easy to achieve while maintaining high accuracy and product quality.

Rigid and flexible components

Which materials are suitable for insert molding?

For applications requiring sealing, damping, or ergonomic features, insert molding can also be combined with soft plastics such as TPE or TPU. These materials provide flexibility and grip while forming a strong, durable bond with harder base materials or metal inserts. Our specialists are happy to advise you on which plastic best suits your product and production process.

Insert materials for insert molding

- Metals such as brass, steel, stainless steel, aluminum, or copper provide strength, stiffness, and electrical or thermal conductivity. They are commonly used for threaded inserts, contact points, and structural reinforcements.

- Carbon- and glass-fiber reinforced plastics offer a lightweight, corrosion-resistant alternative to metal while maintaining high strength and temperature resistance.

- Ceramic inserts are used in environments where wear resistance, insulation, or heat resistance is critical.

Other plastics

Is your desired material not listed? There’s a good chance we have experience with it. We work with many more types of plastics than those mentioned above, but we don’t list them all on our website. Feel free to contact us to discuss the possibilities.

Methodology

Our other services

Your product within 8 to 14 weeks

Pricing and

lead times

For plastic components with inserts, material selection, placement method, design complexity, and post-processing directly affect production costs and lead times, while maintaining efficiency and quality.

- Inserts: Material (stainless steel, brass) and quantity (1–5 inserts) influence material costs and cycle time.

- Placement: Manual placement increases labor time and costs for low volumes; automated placement reduces lead time for high volumes.

- Plastic combinations: The choice of plastic affects price and processing time; thermal compatibility prevents defects that could increase costs.

- Design complexity: Complex designs with multiple inserts increase production time, accuracy requirements, and costs.

- Post-processing: Additional finishing or assembly increases labor costs and extends lead times.

- Automation: Fully automated production lowers cost per part in large series; hybrid solutions optimize the balance between cost, lead time, and flexibility.

Our cases

Examples of injection molding projects

FAQ

Frequently asked questions about insert molding

Insert molding is a specialized form of injection molding in which a pre-manufactured component is placed into the mold before the plastic is injected.

Insert molding combines plastic with metal or ceramic inserts in a single product and offers key advantages:

- Strong, integrated connection: Inserts are encapsulated directly in the plastic, providing a more robust solution than bonding or welding.

- Reduced assembly work: Eliminates additional assembly steps, saving time and cost.

- Increased functionality: Combines the strength or conductivity of metal with the benefits of plastic.

- More compact designs: Enables smaller and lighter products without sacrificing strength.

The minimum production volume for insert molding is comparable to traditional injection molding. There is no fixed lower limit, but the process becomes cost-effective mainly for medium to large production runs.

Minimum volume

The minimum volume is driven primarily by mold costs—the fixed investment required to manufacture the mold. To recover this investment, production volumes of several thousand parts are typically required.

The cost difference between insert molding and standard injection molding is mainly determined by the following factors:

- Tooling costs: Comparable to or slightly higher than standard injection molding.

- Unit production costs: Higher for low volumes due to added complexity and manual insert placement.

- Large series: Highly efficient due to automation and the elimination of secondary operations.

Conclusion: Insert molding is particularly cost-effective for larger volumes, where higher initial investments are offset by lower cost per part.

Orange plastics

Turn your product idea

into reality?

Testimonials

Clients of Orange Plastics

Our experience with Orange Plastics is very positive. Their expertise in 3D modeling, injection mold development and production, and injection molding itself is impressive. The flexible and thoughtful approach - from development to assembly - has helped us enormously in the success of our project. All in all a great club to work with!

Sylvan Boonstra

The collaboration with Orange Plastics went smoothly from the beginning to the end of our project because the lines are very short and they can switch quickly. In addition, they deliver good quality products within the tight deadline. All in all, a company that we can definitely turn to for future projects!

Julia van Bloois

Very fast and quality service. We will definitely come back for our next project.

Jen Rossey

Good service and generous thoughts. Even after the product has been delivered, they continue to help.

Dennis Bartels

Excellent cooperation with Orange Plastics during the development and production of our product. Together we developed a beautiful, high-quality product. In short, a nice company to do business with.

Cornelis van der Kuijl