Orange Plastics

Plastic injection molding – From

Idea to Final Product

Injection molding

More than 20

years of experience in various sectors

At Orange Plastics, we work with you from the initial idea to a fully realized product. Our team combines creativity and technical expertise to provide guidance on design, manufacturability, and sustainability.

Using recycled materials, circular processes and our production facilities in the Netherlands and China, we deliver high-quality plastic products that have a minimal ecological footprint and are produced quickly and reliably, while always focusing on innovation.

The process

How does

injection molding work?

Injection molding is a manufacturing process in which molten plastic is injected under high pressure into a mold and then cooled.

1. Material preparation

Plastic granules (for example PP, ABS or PA) are dried and fed into the injection molding machine. The screw in the cylinder heats and melts the material, turning it into a homogeneous molten mass.

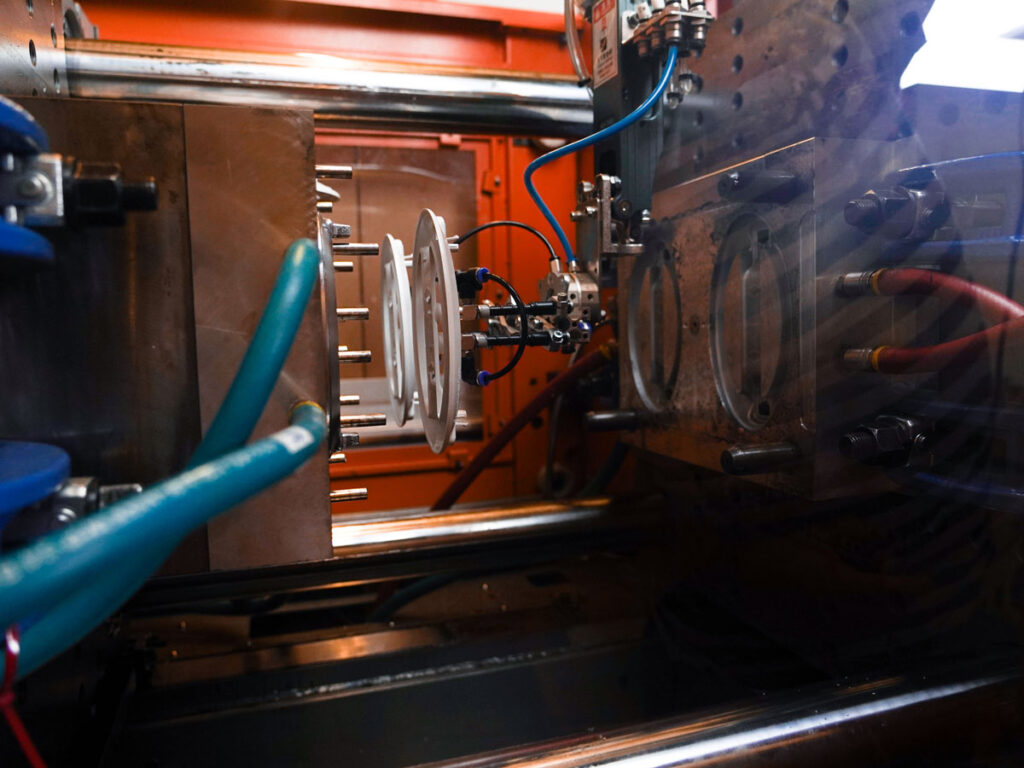

2. Injection & molding

The molten plastic is injected under high pressure into the closed mold. The mold cavity precisely defines the shape and details of the final product.

3. Cooling & solidification

Once the mold is filled, cooling water circulates through channels in the mold steel. This solidifies the plastic, giving the product its final dimensions and strength.

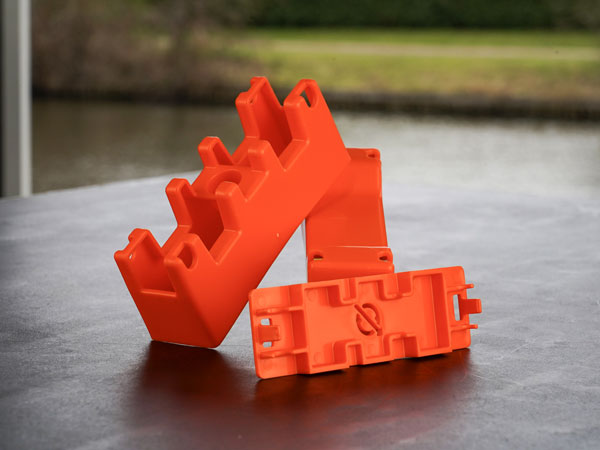

4. Ejection & finishing

The mold opens, and the cooled product is automatically ejected by ejector pins. Excess material or flash is removed, and if necessary, the product undergoes assembly or surface finishing.

5. Inspection & process optimization

During and after production, products are checked for dimensions, color, strength and appearance. Process parameters can be adjusted to ensure consistent quality and efficient series production.

How we do it

Our approach

At Orange Plastics, we guide you through every stage of the injection molding process, from the initial idea to the finished product. With our years of experience, technical expertise and focus on sustainability, we help you get the most out of every design.

Step 1: Design and optimization

You provide the product design

Not every product can be easily produced through injection molding. Several factors come into play, such as:

- The shape and wall thickness of the product

- The complexity of the design

- The type of plastic chosen and its properties

We help you assess the feasibility, manufacturability and sustainability of your design. Together, we identify potential optimizations and provide concrete improvement suggestions.

Through this close collaboration, we achieve the perfect final result.

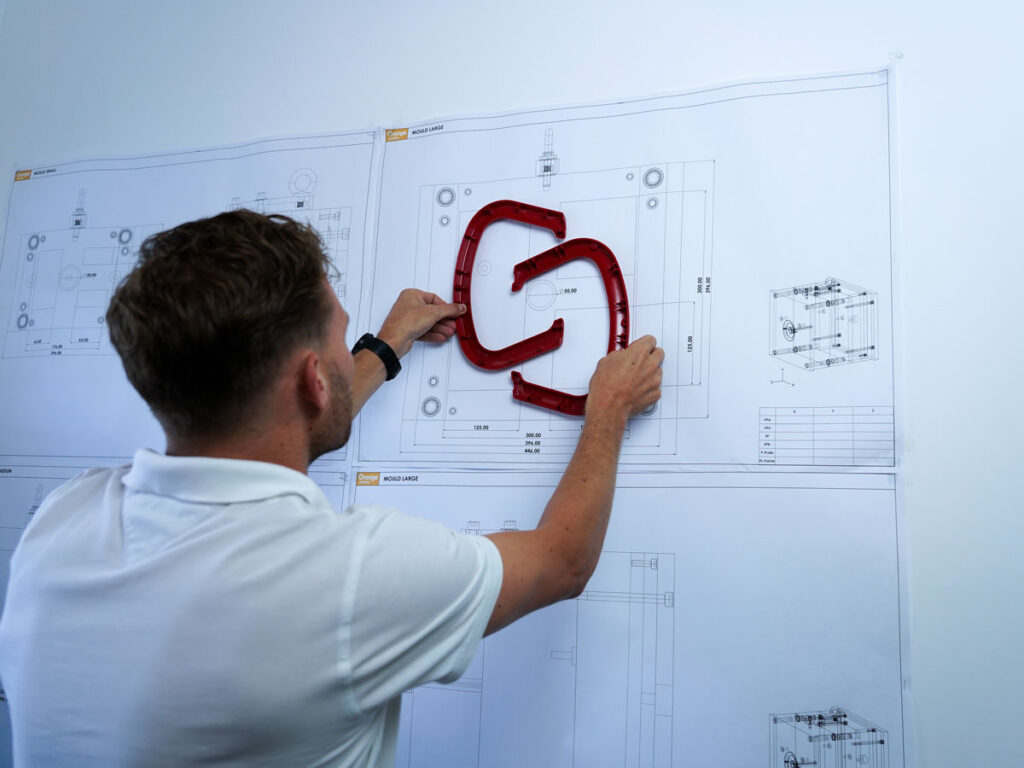

Step 2: Mold making

Based on your 3D product design, we manufacture the injection molds. These molds are created from detailed 3D drawings and fully produced in-house, with every product detail carefully considered.

Thanks to our years of experience in injection molding and in-depth knowledge of mold flow analysis, we can:

- Identify potential issues in mold production at an early stage

- Produce efficiently and accurately

- Ensure the quality of the final product

Once all details have been thoroughly reviewed and the prototype is approved by you, we begin full-scale production.

Step 3: Injection molding production

With production facilities in the Netherlands and China, we always select the most cost-effective location for your project.

- Larger products are usually manufactured in the Netherlands

- More complex products are often produced in China

After injection molding, your products can receive a finishing touch upon request to achieve an attractive final result. Possible techniques include:

- Wet painting

- Printing

- 3D printing

Step 4: Assembly

Some products require assembly after production. We can handle this because we know and understand the individual components.

At all our production sites, we offer assembly services, including:

- Standard assembly

- Assembly in cleanrooms

- Collaboration with social workshops (in the Netherlands)

It is also possible to integrate non-plastic components into your plastic products.

Step 5: Delivery

Virgin & recycled materials

Types of plastics and possibilities

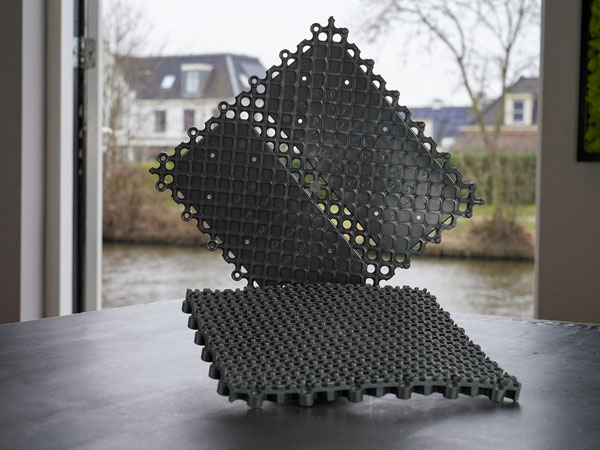

At Orange Plastics, we work with a wide range of plastics – from standard thermoplastics to high-performance engineering plastics and sustainable alternatives such as recycled plastics and bioplastics. Each material has its own unique properties and applications. Our specialists are happy to advise you on which plastic best suits your product and production process.

Sustainable materials and circular injection molding

We can injection mold the plastics mentioned above using both virgin and recycled materials. In addition, we lead the way in circular injection molding: we design and produce with reuse in mind, minimize waste, and choose biobased raw materials whenever possible. In this way, we combine quality, innovation, and sustainability in every product we create.

Other plastics

Is your desired material not listed? There’s a good chance we have experience with it. We work with many more types of plastics than those mentioned above, but we don’t list them all on our website. Feel free to contact us to discuss the possibilities.

Methodology

Our injection molding

techniques

At Orange Plastics, we use a variety of injection molding techniques to ensure the optimal method for each product and application. From prototypes to large-scale production, we have the knowledge and experience to manufacture your plastic components accurately and efficiently.

Injection molding production

Injection molding production is our standard technique for series manufacturing of plastic components. Using modern injection molding machines, we produce high volumes with consistent quality, precision, and efficiency. It is ideal for parts used in large quantities across various industries.

Prototype injection molding

With prototype injection molding, we can quickly and flexibly produce small series of plastic parts. This is perfect for design validation, testing, and market introductions before moving to large-scale production. This method allows you to produce small quantities without high costs and to quickly improve your product based on feedback.

Overmolding

Insert molding

Your product within 8 to 14 weeks

Pricing and

lead times

- Design: Complex shapes or high precision require specialized molds and techniques.

- Quantity: Larger series reduce the unit price; small series are more expensive.

- Material: Standard plastics, engineering plastics or recycled materials influence the costs.

- Post-processing: Extra steps such as assembly, overmolding or finishing increase the price.

- Mold making: 6–8 weeks, depending on complexity and material.

- Series production: 2–6 weeks after approval of the prototype or test series, depending on quantity and material choice.

Capacity and production volumes

In plastic injection molding, we can flexibly respond to various production needs:

- Minimum and maximum series: Depending on the size and complexity of the product, production can be efficient starting from 1,000 pieces, with possibilities for unlimited quantities.

- Product sizes and tolerances: Suitable for products from 1 gram to 12.5 kilograms.

Industries

Application in various sectors

Beauty

Building & construction

Consumer products

Elektronics

Industrial

Medical

Packaging

Aerospace

Transport

Our cases

Examples of injection molding projects

FAQ

Frequently asked questions about injection molding

Injection molding is the process in which molten plastic is injected under high pressure into a mold. At Orange Plastics, we combine precision and technical expertise to produce high-quality plastic components, from small precision parts to larger applications, with a focus on quality, sustainability and efficient production.

At Orange Plastics, the process from design to production usually takes a few weeks to several months, depending on complexity, mold development and material selection. We closely manage each project, provide advice on design and manufacturability, and ensure an efficient and reliable production process so that your product is realized quickly and sustainably.

We produce from approximately 1,000 pieces. This is what we call “small series.” Below this quantity, injection molding is often not cost-effective, but if necessary, we are happy to explore creative solutions.

We work with almost all thermoplastics: PP, ABS, PA, PE, TPE and more. In the Netherlands, we use almost exclusively recycled materials. This is a deliberate choice that aligns with our vision of circular and future-proof manufacturing. Increasingly, we also use bioplastics. We work with you to determine the best solution, both technically and sustainably.

Yes, you can choose from existing colors or have a custom color mixed. Transparent or UV-resistant materials are also available.

Orange plastics

Turn your product idea

into reality?

Testimonials

Clients of Orange Plastics

Our experience with Orange Plastics is very positive. Their expertise in 3D modeling, injection mold development and production, and injection molding itself is impressive. The flexible and thoughtful approach - from development to assembly - has helped us enormously in the success of our project. All in all a great club to work with!

Sylvan Boonstra

The collaboration with Orange Plastics went smoothly from the beginning to the end of our project because the lines are very short and they can switch quickly. In addition, they deliver good quality products within the tight deadline. All in all, a company that we can definitely turn to for future projects!

Julia van Bloois

Very fast and quality service. We will definitely come back for our next project.

Jen Rossey

Good service and generous thoughts. Even after the product has been delivered, they continue to help.

Dennis Bartels

Excellent cooperation with Orange Plastics during the development and production of our product. Together we developed a beautiful, high-quality product. In short, a nice company to do business with.

Cornelis van der Kuijl